- Reduced complexity – nyloflex® XAH Digital Plate for the flexible packaging and tag & label markets is suitable for solvent based and UV ink systems.

- Reduced operating costs – AIF (Anti-Ink-Fill) technology enables fewer cleaning stops.

- nyloflex® Xpress Thermal Processing System sustainably delivers high quality thermal plates, comparable to solvent quality, in less than one hour.

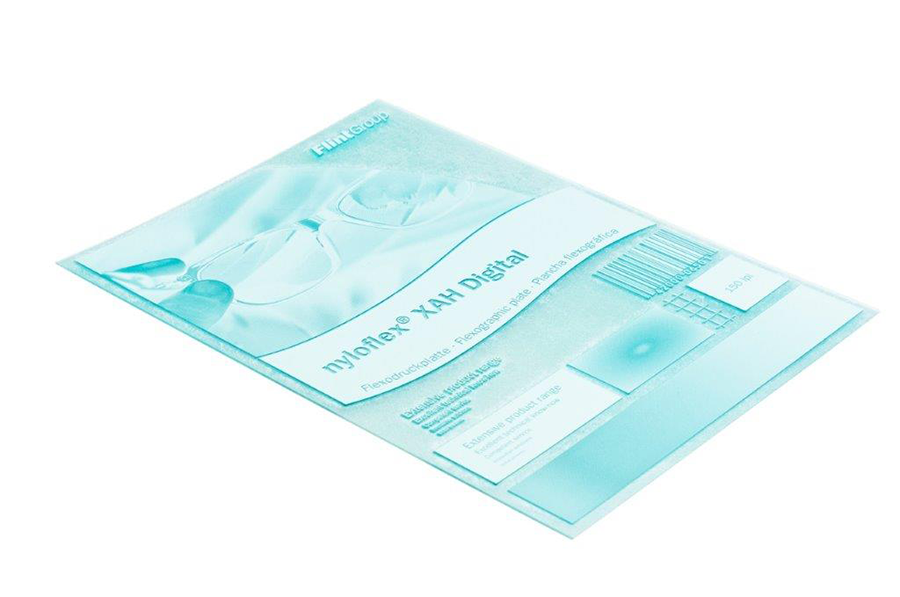

Stuttgart, Germany, August 19, 2019 – The nyloflex® XAH Digital, a hard round top dot plate with a smooth surface, is the latest addition to Flint Group’s fast-growing line of nyloflex® thermal printing plates designed specifically for use in its nyloflex® Xpress Thermal Processor. The new flexographic plate is formulated with a special AIF technology that keeps plates cleaner on press and results in faster print runs with fewer press stops. In addition, plate makers can expect to achieve all of the benefits of the nyloflex® Xpress Thermal System – such as lower operating costs, higher sustainability and the quality of a solvent processed plate – producing plates in under one hour from imaging to finishing. The innovative plate is perfectly in line with the company’s promise of providing solutions which are “Better. Faster. Easier to use.”

“Even though the market as a whole is rapidly moving toward inherently flat top dot plates, many of our customers are still using a substantial amount of standard digital plates with round top dots. There are also companies that have invested in flat top systems and prefer to use those systems along with surface screening to create a customized plate surface for their specific applications,” explains P.J. Fronczkiewicz, Product Manager Flint Group Flexographic. “We also incorporate our AIF technology into this plate to address the issue of plates filling in with ink during printing. This frustrating problem – which can lead to dirty print – can occur in flexible packaging printing with solvent based inks as well as with some UV inks used in the tag & label market. The advantage of AIF technology is that it provides outstanding sub-surface ink repellence to keep the plate screens and reverses clean during print runs, so printers have fewer press stops and can achieve faster press speeds,” concludes Fronczkiewicz.

The nyloflex® XAH Digital is a high durometer flexo plate that reproduces sharp details of the finest elements, screens, text and line work for superior quality print. The plate is perfect for applications with solvent-based inks and UV inks used in the flexible packaging and tag & label markets, particularly those where special AIF technology is required, and for plate makers who have flat top systems already in place. The nyloflex® XAH Digital Plate is optimized for use exclusively with Flint Group’s nyloflex® Xpress Thermal Processing System.

Incorporating a clever heating system that utilizes very low energy, the nyloflex® Xpress Thermal Processing System is extremely effective at controlling the temperature of the plate surface; therefore, plates never overheat, and there is no need for extra components, such as a chiller or vapor handling system to deal with these effects. The result is that plate makers are able to reduce the energy consumption of plate processing by up to 88% versus competitive thermal systems, and up to 94% compared to solvent processing, with almost no volatile organic compounds (VOCs) or vapors generated. The nyloflex® XAH Digital Plate coupled with the nyloflex® Xpress Thermal Processing System offers an optimal combination of components that provides a more sustainable solution to flexo plate makers and supports the printing industry in meeting its sustainability goals.

nyloflex® XAH Digital Plates are commercially available in 1.14 mm (0.045 in.) and 1.70 mm (0.067 in.) thicknesses and in varying plate sizes. The nyloflex® Xpress Thermal Processing System is available in either F IV (1067 x 1524 mm / 42 x 60 in.) or the soon-to-be released F V (1270 x 2032 / 50 x 80 in.) format sizes.

These advancements are the latest examples of Flint Group’s dedication to provide its customers products which are Better. Faster. Easier to use.

For more information or to request samples or a personal sales call, please contact Flint Group at www.flintgrp.com or email info.flexo@flintgrp.com.

Flint Group

Flint Group is dedicated to serving the global printing and packaging industry. The company develops, manufactures and markets an extensive portfolio of printing consumables and printing equipment, including:

a vast range of conventional and energy curable inks and coatings for most offset, flexographic and gravure applications; pressroom chemicals, printing blankets and sleeves for offset printing; photopolymer printing plates and sleeves, plate-making equipment and flexographic sleeve systems; pigments and additives for use in inks and other colourant applications; Flint Group also designs, develops and delivers web-fed digital colour presses for labels and packaging applications, document printing, as well as commercial printing as well as platemaking equipment for the newspaper industry and computer-to-plate (CtP) solutions for the commercial printing market; With a strong customer focus, unmatched service and support, and superior products, Flint Group strives to provide exceptional value, consistent quality and continuous innovation to customers around the world. Headquartered in Luxembourg, Flint Group employs some 7500 people. Revenues for 2018 were € 2.1 billion. On a worldwide basis, the company is the number one or number two supplier in every major market segment it serves. For more information, please visit wwww.flintgrp.com

nyloflex® is a registered trademark of Flint Group and/or its affiliates.

Source: Flint Group