Bobst China announces major presence at Print China 2019, continuing its China 4.0 strategy and showcasing latest innovations

Visitors can see BOBST folder-gluers and die-cutters in action in Hall 3 at stand 3-C104

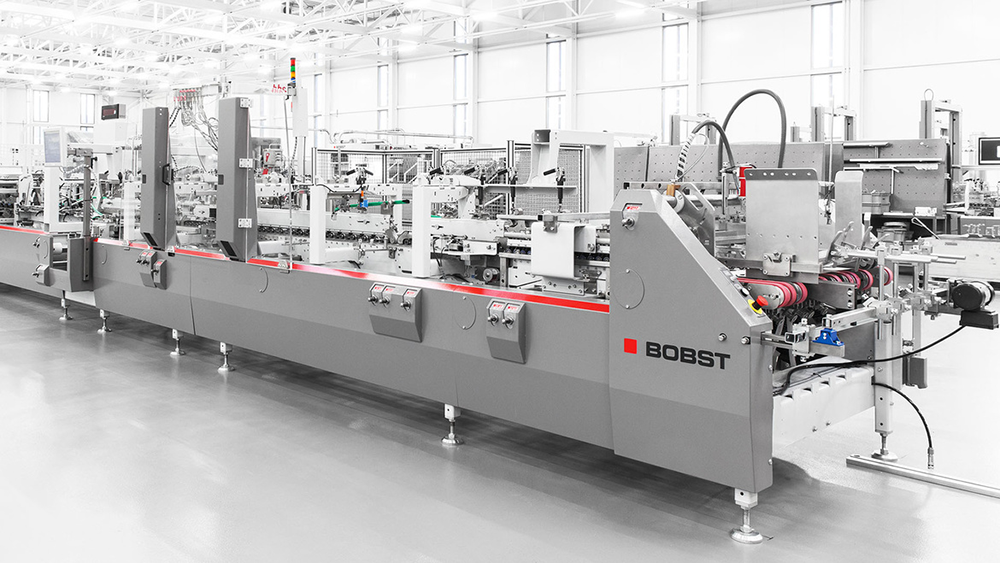

BOBST will showcase some of its principal innovations aimed at boosting productivity at Print China 2019, one of the world’s leading printing technology exhibitions, which is taking place from April 9th to 13th in Dongguan city, China. On display will be two of BOBST’s leading folder gluers, FULONG III 50 A1 and MEILONG III 110 A2, and two of most popular die-cutters, SP 106 E and SP 106 ER, along with an impressive range of peripherals and devices capable of increasing productivity even further.

Only last March, Bobst China launched a new strategy, committing to deliver tailored solutions for the dynamic and highly competitive Chinese market. “Bobst China’s unique know-how and technology will help clients reach their goals in China and beyond,” added Mr. Huang, the Sales Director of Bobst Shanghai. “We launched the initiative ‘Proximity and Performance’ last year. Essentially it means that our clients are guaranteed the very best in Swiss-quality technology, with local production and a localized customer support service to match. It reflects our very deep commitment to the Chinese market, and we are very excited to discuss this in more detail with attendees at Print China 2019.”

Visitors will be able to see FULONG III 50 A1, an extremely efficient and compact folder-gluer. The modular all-rounder helps customers to diversify their product range. Versatile and stable, this user-friendly folder-gluer delivers consistent high-end quality and amazing productivity. During the exhibition, this highly competitive folder-gluer will be combined with EASYFEEDER / BATCH INVERTER 4 and CARTONPACK 4, to form a high-performance folding-gluing line. The inlet peripheral EASYFEEDER / BATCH INVERTER 4 ensures smoother, faster and simpler feeding of blanks. It allows feed-end operatives to be more productive, or to multi-task, while the consistent feeding reduces both production stops and the risk of marking. Meanwhile, the finished boxes will be efficiently packed by CARTONPACK 4. It provides fully automatic intelligent packing, with settings, motorized movements and MATIC for repeated box orders. All this equipment allows for complete automation of the folding-gluing process, requiring almost no operator intervention.

Also on show will be MEILONG III 110 A2. This amazingly versatile folder-gluer can produce a large number of box styles in a wide range of materials. It is known for its superb productivity –

running at speeds up to 450 meters per minute – and for delivering boxes of extremely high quality. It will be equipped with SPEEDWAVE 2, the no-hooks device for running crash-lock boxes at maximum speed with the greatest precision. The efficient packing of the finished boxes will be made possible with COLLECTING TABLE, the compact and user-friendly packer.

Attendees at Print China 2019 will also be able to see two flatbed die-cutters it in action: SP 106 ER and the new SP 106 E. These die-cutters improve both quality and productivity throughout the entire carton conversion operation. Highly automated and equipped with the advanced HMI SPHERE, they provide easy set-ups, fast changeovers and therefore maximum up-time. BOBST technologies such as Autoplaten® and Centerline® can guarantee a perfect die-cutting – and stripping – result, which will convince even the most demanding clients. SP 106 ER will also be equipped with an ingenious sampling device and with the Automatic Pile Transfer (ATP) system, which allows the complete automation of the material logistics.

“Proximity and Performance”,the promise is not only reflected in specific product solutions, but is also an integral part of the extended Service offer. The core of this offer is to provide maintenance and support to customers so that they can increase productivity, enhance the quality of the production and optimize the availability of their machines. “Helpline Plus, Downtime Tracking, Remote Monitoring and other new technologies will help our customers to maximise the productivity of their machine,” said Mr. Wilson Huang. “The digitalization and automation of various processes help to increase the efficiency, availability and productivity of the different production processes. We therefore strive to continually improve our products and services by innovating and including new technologies.”

Please click here to register and to arrange a meeting at Print China 2019

Source: Bobst Mex SA, Switzerland